GEOPOL®

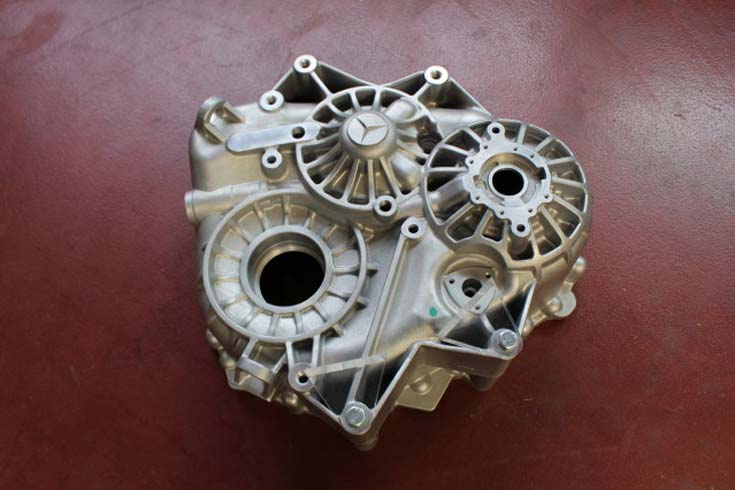

is an inorganic sand binder designed to reduce the fume and odour levels during the manufacture of cores and castings, with minimal environmental impact. It can reclaim up to 90 % of sand wasted during the proces. GEOPOL® is a unique geopolymeric, modified silicate no-bake binder. It is suitable for use with virtually all metal and alloy types. It creates a cleaner and more sustainable foundry environment.

The low addition levels, compared to sodium silicates, result in:

Improved flowability

Higher mould density

Improved shake out

Better surface finish

Hardener levels can be adjusted between 10% and 18% of binder weight, giving more flexibility with the strip time, without altering bench life.

The environmental benefits of GEOPOL® – for boxed and boxless mould production – include:

- No VOCs

- Minimal soluble carbon compounds

- Virtually no emissions in the foundry environment during moulding, pouring or shakeout

GEOPOL® enables the operation of a clean foundry environment, as the sand waste does not contain any phenols or leachable products. It has lower hydrogen potential and can be mechanically reclaimed:

- Up to 50% reclamation with single, simple attrition

- Up to 90% reclamation with double/intensive attrition

GEOPOL® was originated in the Czech Republic by SAND TEAM CZ, and further commercially developed by SAND TEAM CZ and John Winter Ltd UK. It was developed in response to the casting industry’s increasing need for a process that tackles the issues of fumes, odour and waste disposal.

GEOPOL® is now available worldwide, having been proven to transform the working environment in several foundries in Europe, North America and the Middle East.

English

English Czech

Czech German

German